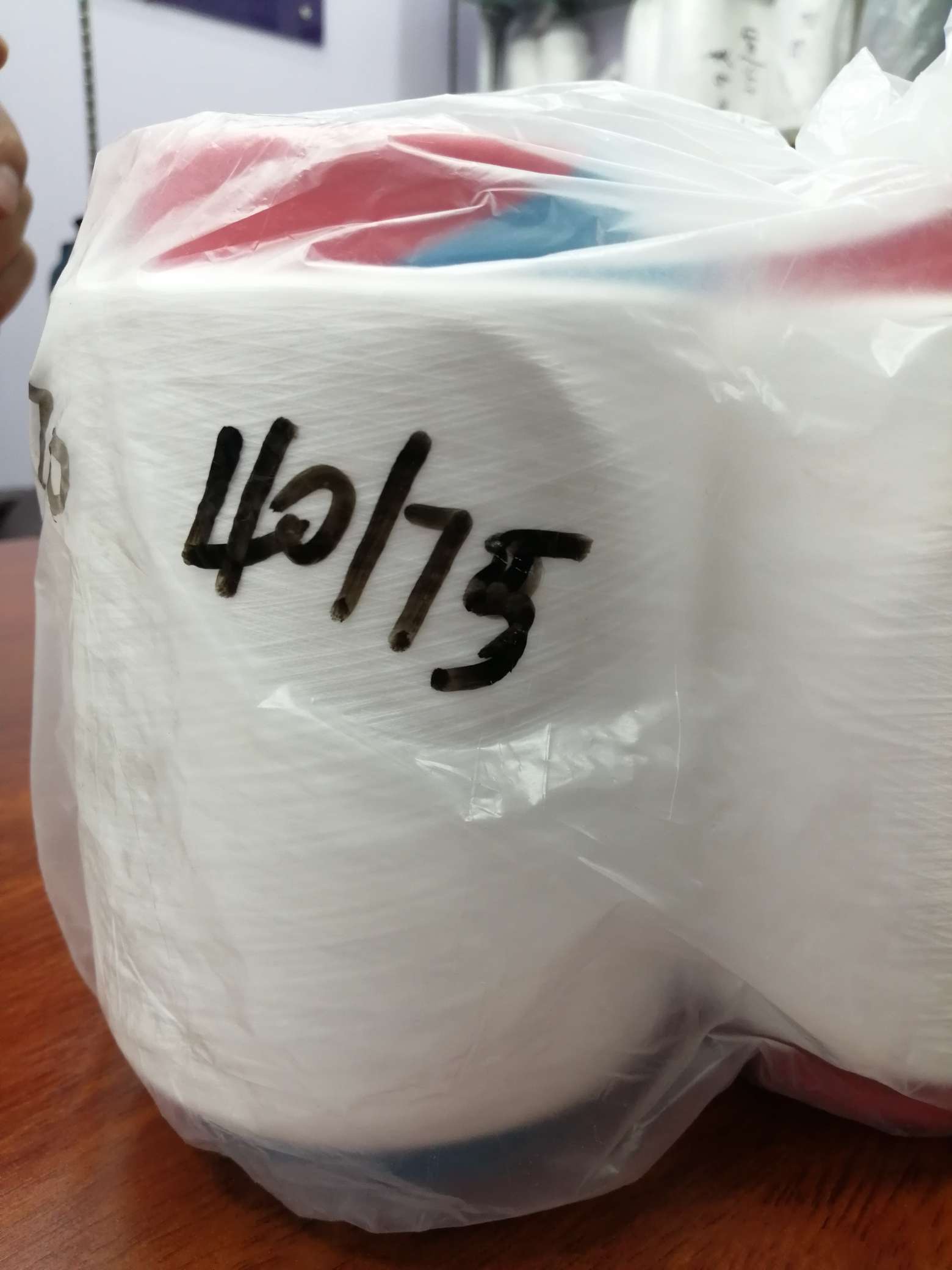

A Deep Dive into Spandex Yarn 40/75

The textile industry is an ever-evolving field where understanding specific material compositions can yield better products. Today, we will delve into the specifics of Spandex Yarn 40/75, a widely acclaimed elastane fiber known for its versatility and strength.

Unpacking the Label: What Does 40/75 Mean?

The numerals in "40/75" refer to two important measurements. The first number (40) pertains to the denier of the yarn, indicating its thickness, while the second number (75) signifies the yarn count, dictating how fine or coarse the fibers are. This standard nomenclature helps manufacturers maintain consistency across different batches and brands.

For comparison, other common designations like 30/70 or 50/100 follow similar principles but vary in thread thickness and elasticity properties. Such specifications play crucial roles in textile manufacturing as they determine the yarn’s suitability for various applications, ranging from ultra-thin fabric pieces to robust outdoor wear.

Core Composition: The Building Blocks of Spandex Yarn 40/75

Spandex Yarn 40/75 primarily comprises segmented polyurethane—a polymer known for exceptional stretchability. The chemical structure involves long chains of flexible segments linked with shorter rigid segments. This configuration allows the yarn to extend up to five times its length without losing elasticity.

What sets Spandex apart from other elastic fibers like rubber or Lycra is this unique molecular composition, providing remarkable recovery properties after stretching. Its usage isn't limited to comfort; it also adds durability and flexibility to textiles, making it indispensable for modern garment manufacturing.

Production Process: From Raw Materials to Finished Yarn

The production journey of Spandex Yarn 40/75 begins with deriving polyether or polyester precursors, which undergo a series of chemical reactions to produce prepolymers. These prepolymers react further to form polyurethane-based solutions spun into fibers via wet or dry spinning techniques.

Technological advancements have streamlined these processes over time. Modern machinery offers precise temperature controls and environmental standards, ensuring consistent fiber dimensions and enhanced qualities. Additionally, rigorous quality control measures such as tensile testing at multiple stages help ensure that only the highest-grade yarn reaches consumers.

Quality Parameters: What Makes Spandex Yarn 40/75 Stand Out?

Not all spandex yarns are created equal, and Spandex Yarn 40/75 stands out due to several key parameters. First, it boasts impressive tensile strength, meaning it can withstand significant tension before breaking. This property is paramount for sportswear and lingerie where durability is essential.

Furthermore, the high degree of elasticity allows garments made from this yarn to return to their original shape after being stretched. Comfortable and breathable, Spandex Yarn 40/75 ensures wearers don’t feel confined, even during strenuous activities. Its resilience against wear-and-tear also means that clothes maintain their appearance longer than those made from inferior yarns.

Applications and Usability: Where Spandex Yarn 40/75 Shines

The versatility of Spandex Yarn 40/75 makes it suitable for numerous textile products. It is particularly favored in activewear, thanks to its combination of strength, elasticity, and breathability. Sports bras, leggings, and compression shirts often use this yarn because it supports muscle movement while maintaining high comfort levels.

Additionally, the intimate apparel industry values Spandex Yarn 40/75 for similar reasons. Lingerie items like shapewear and underwear benefit significantly from its ability to provide controlled, comfortable fit. Everyday clothing also incorporates this yarn into stretchy jeans and fitted t-shirts, offering fashionable yet practical enhancements.

Comparative Analysis: Spandex Yarn 40/75 vs. Other Elastic Yarns

When comparing Spandex Yarn 40/75 with other elastic yarn types, several performance aspects come to light. While some cheaper options may offer basic stretch capabilities, they often fail in terms of durability and recovery post-stretching. Users frequently report sagging or loss of shape after minimal use with subpar alternatives.

In contrast, Spandex Yarn 40/75 provides excellent cost-effectiveness through sustained performance, translating into fewer replacements and better ROI for garment manufacturers. Positive reviews from textile industry professionals echo its value proposition, emphasizing reliable stretch and ease of integration into diverse designs.

Sustainability and Environmental Impact

As consumers grow more environmentally conscious, sustainable practices in manufacturing gain importance. Fortunately, advanced technologies enable eco-friendly production methods for Spandex Yarn 40/75, reducing carbon footprints and waste. Some facilities implement closed-loop systems to recycle solvents used during fiber synthesis.

Moreover, ongoing research focuses on enhancing biodegradability and recyclability, aligning future trends towards greener textiles. Companies leading these initiatives set benchmarks for the entire industry, proving that sustainability doesn't demand compromising on quality or performance.

Tips for Selecting High-Quality Spandex Yarn 40/75

While Spandex Yarn 40/75 boasts many advantages, choosing the right product requires attention. Prospective buyers should prioritize yarns from reputable suppliers like Fujian Jiayi Nylon Co., Ltd, known for adhering to stringent quality standards. Checking certifications and third-party evaluations can further verify claims regarding tensile strength, elasticity, and overall integrity.

It is also wise to scrutinize user reviews to identify any recurring issues or commendable features. Avoid vendors that lack transparency about their manufacturing processes or have questionable track records. By doing so, you ensure a purchase that delivers effective results across varied applications.

Conclusion: The Future of Spandex Yarn 40/75 in Textile Manufacturing

Innovation continues to redefine Spandex Yarn 40/75 utility and applicability within the textile sector. Emerging trends point towards integration into smart fabrics, healthcare textiles, and specialized athletic equipment. Improved sustainability promises not only heightened ecological responsibility but also increased market readiness for distinctive consumer demands.

Ultimately, comprehending the complex makeup and superior qualities of Spandex Yarn 40/75 arms textile enthusiasts and professionals with valuable insights. Investing in premium materials translates to improved product longevity, satisfied customers, and thriving business ventures, cementing this yarn type's pivotal role in contemporary fashion and beyond.